Understanding Hardness

The hardness of a material is often one of the first criteria considered when choosing a thermoplastic elastomer (TPE). GLS produces standard products ranging in hardness from 3 Shore A (softest) to 95 Shore A (hardest). Hardness is defined as a material’s resistance to indentation when a static load is applied.

Hardness is also related to other important physical properties such as tensile and flexural modulus. Confusion can arise when discussing hardness due to the variety of measurement scales and its relationship to other material properties.

Measurement of Hardness

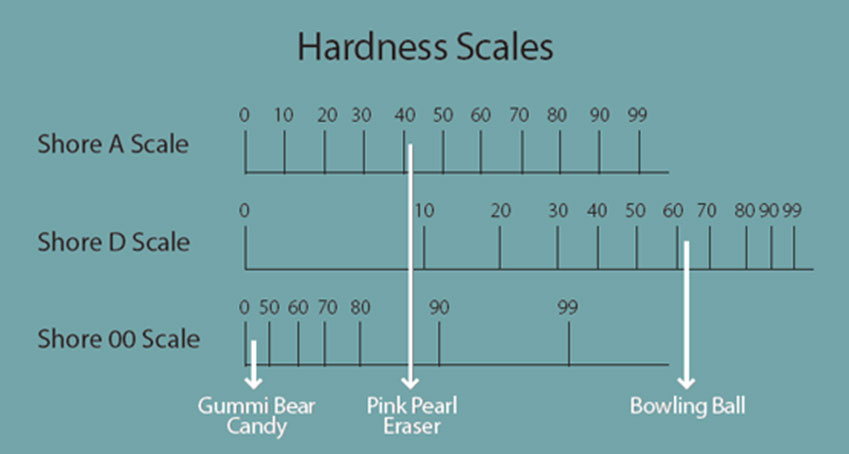

The most common instrument for measurement of hardness is called the Shore durometer. This instrument measures the depth of penetration from zero to 0.100 inches. A zero reading on the scale means the indenter penetrated with maximum depth. Likewise, a reading of 100 indicates no penetration of the indenter. The most common scale for TPE’s is the Shore A scale. The Shore A durometer consists of a blunt indenter with moderate spring force. Shore A instruments are less accurate when readings are above 90. The Shore D durometer is more appropriate when hardness levels are above 90 Shore A. This instrument uses a sharper indenter and higher force. Softer TPE’s use the Shore 00 scale for measurement of materials below 5 Shore A. Most soft gels and soft foam rubbers are measured using the Shore 00 scale.

Methods

Most materials will resist initial indenture but will yield further over time due to creep or relaxation. Durometer readings can either be taken instantaneously or after a specific delay time, which typically range between 5 and 10 seconds. An instantaneous reading will typically give a higher (or harder) reading than the delayed readings. Delayed readings are more representative of not only the hardness of the material, but the resiliency. A weak, less elastomeric material will creep more than a higher strength, more resilient material. GLS reports hardness values utilizing the 10 second reading.

Relationship to Other Properties

Hardness is often confused with other properties including flexural modulus. Both properties reflect how the product feels to the touch. Flexural modulus measures the materials’ resistance to bending, and hardness measures the materials’ resistance to penetration. Creep resistance and tensile strength are also directly related. Softer TPE’s will creep more and have less tensile strength than a harder material. Coefficient of Friction (COF) varies indirectly with hardness. As the hardness increases, the COF generally decreases. Generally, higher hardness materials have better abrasion resistance. The relationship between different hardness scales can be found in the figure above. Some common materials are listed are placed on the respective hardness scale.